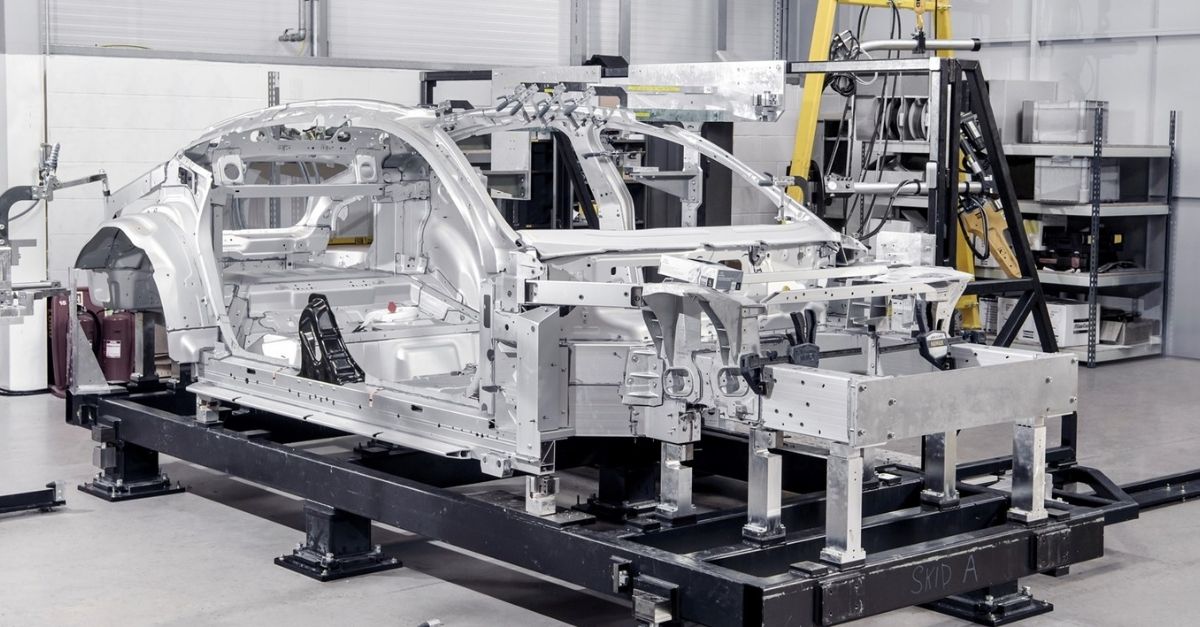

Polestar has revealed that its upcoming model, the Polestar 5 electric performance GT, will feature a new, bespoke, bonded aluminium platform.

Bonded aluminium is lightweight and rigid, enhancing the safety and performance levels of electric vehicles, but employing the technology has previously been labour-intensive and difficult to use in mass production.

However, Polestar’s 280-strong team of Midlands-based engineers has resolved this problem by developing an entirely new, faster manufacturing process that develops both body and platform in unison.

As a result of the new materials and techniques involved, the completed platform and body is expected to weigh less than that of cars in smaller segments.

Thomas Ingenlath, Polestar CEO, said, “Our UK R&D team is one of Polestar’s greatest assets. Their mix of engineering and technological expertise enables us to develop advanced, lightweight sports car technology with a creative mindset and a spirit that embraces innovative engineering. This will set Polestar apart in the years to come.”

Pete Allen, Head of Polestar UK R&D, said: “We knew we wanted this car to be lightweight, we knew we wanted high quality and we knew we wanted it quickly. This architecture delivers outstanding dynamic and safety attributes, with low investment technology applicable to high production volumes.”